Impregnation and drying are critical stages in the electric motor winding process, ensuring mechanical stability, electrical insulation, and long-term durability of the windings.

We use Aquanel® VF111T, a water-based impregnating resin developed for electrical insulation of components such as electric motor windings and transformers. This solvent-free varnish is an environmentally friendly and safe choice.

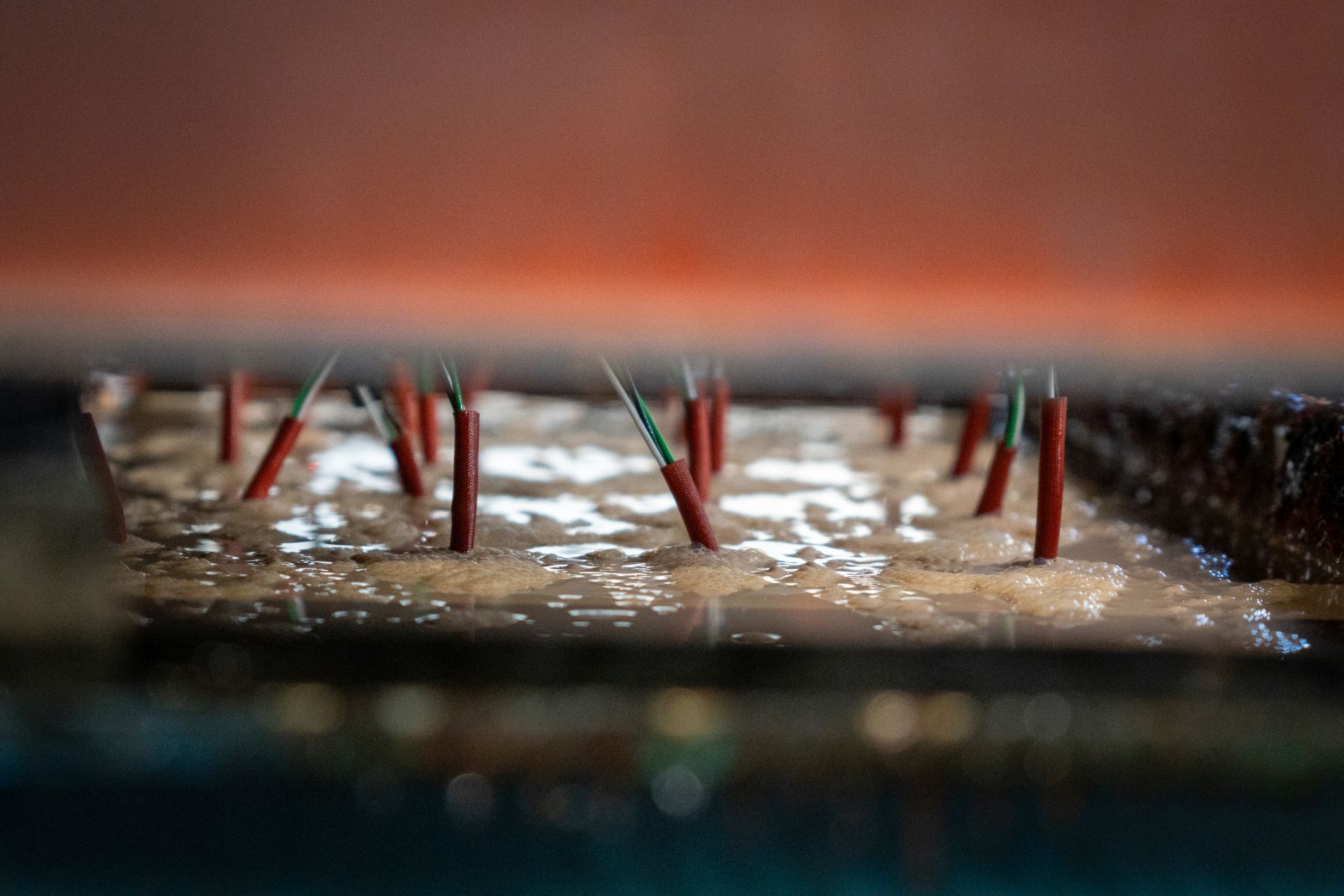

The filling impregnation process and the drying phase are performed using a TECNOFIRMA automatic drying oven.

Main stages of impregnation and drying:

- Preparation – Cleaning and pre-checking windings for uniform coating

- Impregnation – Saturating windings with resin or special varnish to enhance electrical insulation and mechanical resistance

- Excess resin removal – Eliminating surplus material to ensure uniform application

- Drying and polymerization – Curing resin in an automated drying oven for proper adhesion and durability

- Final inspection – Quality verification of the coating to ensure optimal protection and stability of windings