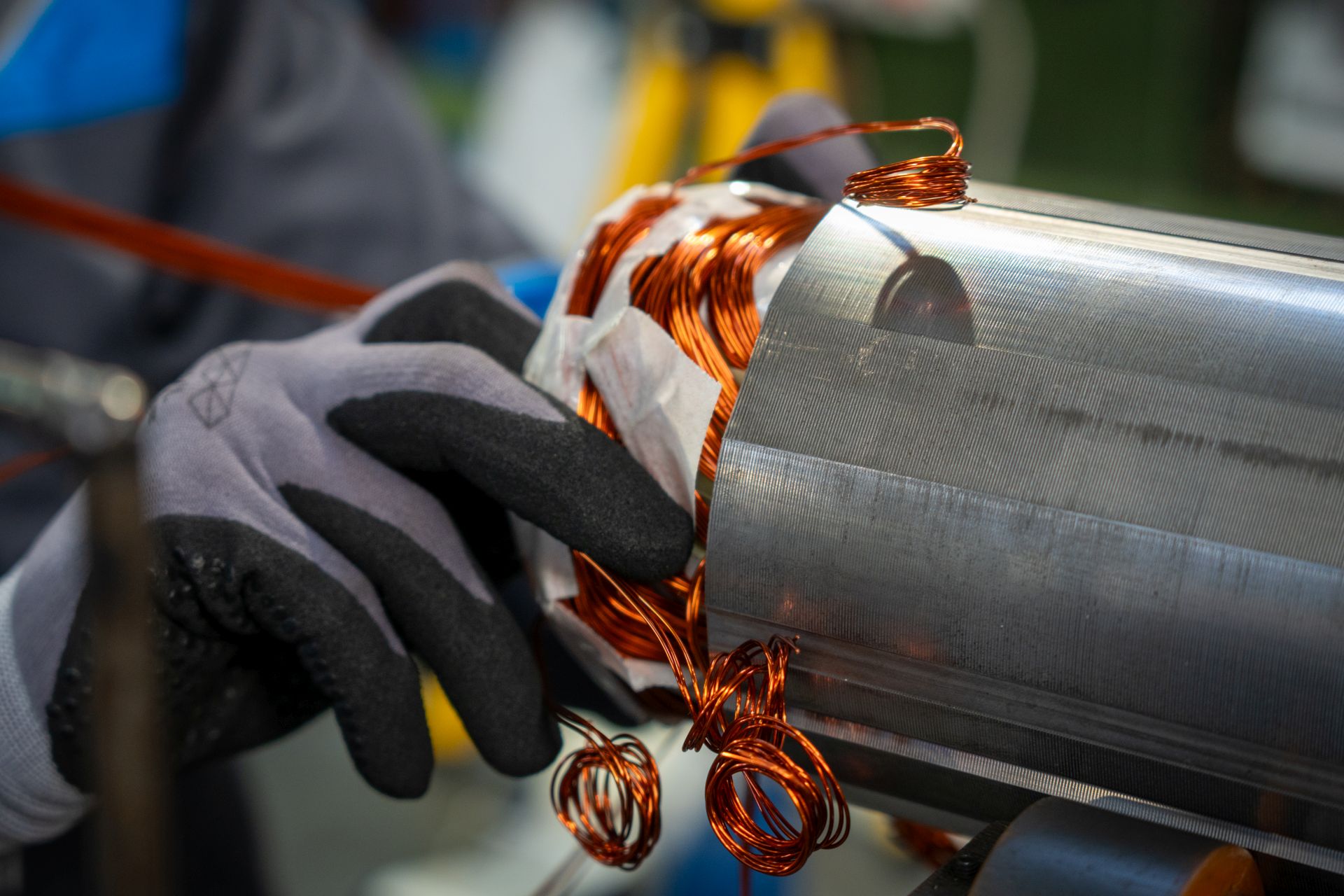

The manual processing phase is essential for the production of special or customized motors where automated processes cannot guarantee the required precision and quality.

To ensure quality, our company has a manual insertion department for the production of non-standard and water-submerged windings, including large sizes.

Main stages of manual processing:

- Manual coil placement – Precise positioning of wires in designated slots

- Manual insertion of insulating materials – Careful application of additional insulation layers

- Adjustments and manual corrections – Fixing defects and fine-tuning for a perfect fit

- Manual lacing and securing – Ensuring stable fastening of windings and other components

- Final manual inspection – Visual inspection of completed winding and quality verification