Pressing and lacing are essential phases in the electric motor winding process, ensuring proper positioning and securing of windings within the motor structure.

These processes contribute to the mechanical stability of the motor, reduce vibrations, and prevent windings from shifting during operation.

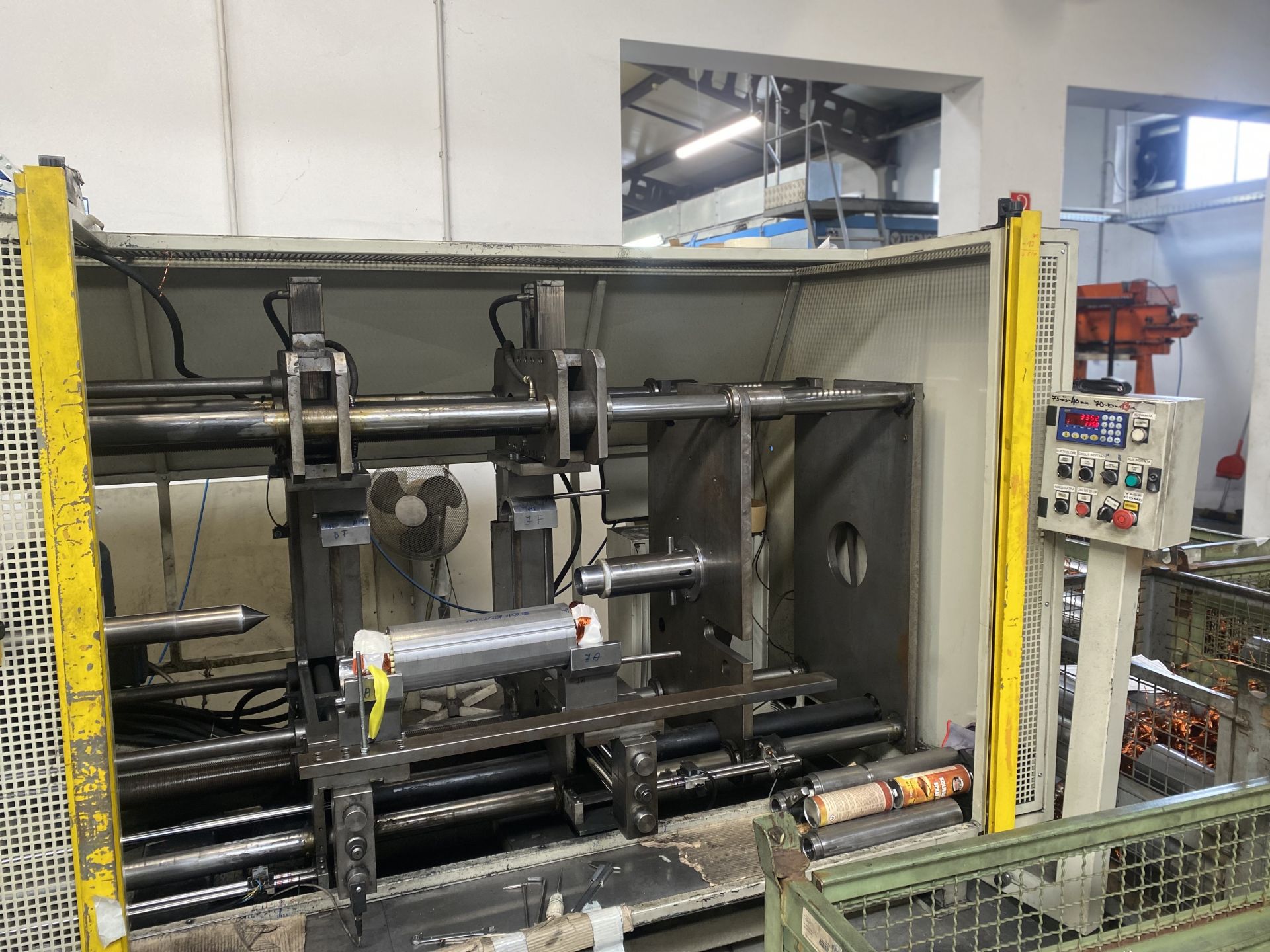

At our company, pressing and lacing are mechanized for stators up to 800 mm in height.

Main stages of pressing and lacing:

- Alignment and preparation of windings – Correct positioning for stable fastening

- Pressing – Applying mechanical pressure to compact and shape windings

- Lacing – Using special tapes or wires to secure windings and prevent movement

- Application of fastening materials – If necessary, varnishes or resins are used for additional reinforcement

- Final inspection – Checking pressing and lacing quality to ensure optimal mechanical stability